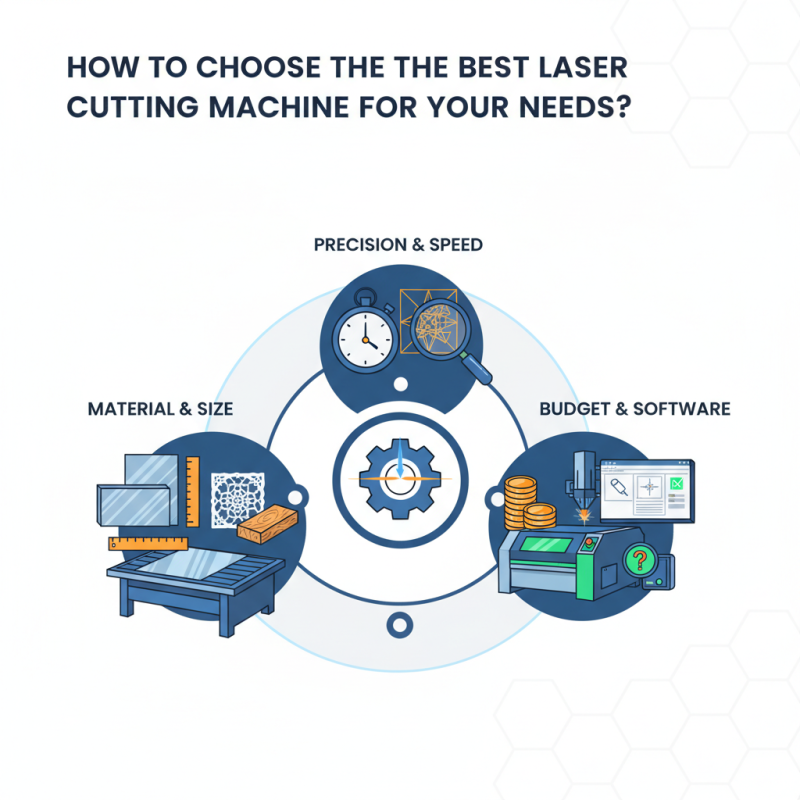

How to Choose the Best Laser Cutting Machine for Your Needs?

When it comes to industrial needs, choosing the right laser cutting machine is crucial. The precision and speed of these machines enhance productivity. Several factors influence this decision.

Understanding your specific requirements is key. The size and type of materials you plan to cut matter significantly. A machine meant for thick metal doesn't suit intricate designs on paper. Additionally, consider the machine's compatibility with software for your projects.

Budget can be a tricky aspect. While lower-priced models may attract you, they could lack essential features. This leads to frustrations down the line, especially if you need to upgrade. Reflect on your long-term goals; investing in quality often pays off better than opting for the cheaper route.

Understanding Different Types of Laser Cutting Machines Available

When selecting a laser cutting machine, understanding the types available is crucial. The market offers three main types: CO2 lasers, fiber lasers, and solid-state lasers. CO2 lasers are versatile, ideal for cutting materials like wood, acrylic, and glass. They account for approximately 60% of the laser cutting market due to their widespread use in various industries. However, they may struggle with metals, which can be a drawback.

Fiber lasers, on the other hand, excel at cutting metals. Their efficiency is notable, with reports indicating they can cut stainless steel at a speed of up to 40 meters per minute. This type is growing rapidly, capturing about 30% of the market share. Despite their advantages, fiber lasers can be more expensive initially and require specific setups for optimal operation.

Solid-state lasers, though not as common, have a unique application in specialized fields. They deliver focused energy but require careful calibration. The lack of widespread understanding about their use can lead to hesitance among potential buyers. Choosing the right machine depends on the primary materials involved and the specific needs of your projects. It's essential to evaluate long-term costs, not just the upfront price, and consider what fits best for your operations.

Key Features to Consider When Choosing a Laser Cutting Machine

When choosing a laser cutting machine, key features are crucial. The type of laser is significant. CO2 lasers are good for non-metal materials. Fiber lasers excel in cutting metals. Evaluate the materials you will work with before making a decision.

Power is another essential factor. Machines range from 30W to 150W. Higher power means faster cuts and thicker materials. However, it can be overkill for thin materials. Assess your needs carefully to avoid wasting energy.

Tips: Always consider the machine’s size. Ensure your workspace can accommodate it. Look at the software compatibility too. A user-friendly interface makes operation smoother.

Be aware of maintenance requirements as well. Some machines need regular upkeep, which can be time-consuming. Weigh the time savings of using a more automated system against its cost. Your choice should ideally reflect both your budget and your long-term goals.

How to Choose the Best Laser Cutting Machine for Your Needs? - Key Features to Consider When Choosing a Laser Cutting Machine

| Feature | Description | Importance |

|---|---|---|

| Laser Type | CO2, Fiber, or Nd:YAG lasers are commonly used. | Determines the materials you can cut. |

| Cutting Speed | The speed at which the machine can cut through materials. | Affects productivity levels. |

| Engraving Capability | Ability to engrave as well as cut. | Versatility in applications. |

| Bed Size | Dimensions of the cutting area. | Determines the size of projects you can work on. |

| Cooling System | Type of cooling system used to prevent overheating. | Ensures consistent performance. |

| Software Compatibility | Types of software supported for design files. | Ease of use and integration into existing workflows. |

| Maintenance Requirements | Frequency and type of maintenance needed. | Affects long-term costs and downtime. |

| Safety Features | Inbuilt safety mechanisms and protective measures. | Ensures safe operation. |

Assessing Your Material Compatibility for Laser Cutting

Choosing the right laser cutting machine hinges heavily on material compatibility. Each material reacts differently to laser cutting. For instance, metals such as steel and aluminum require high-powered lasers, often exceeding 1000 watts. Conversely, materials like wood and acrylic can be effectively cut with lower wattage machines. Industry reports indicate that improper wattage selection can lead to burn marks in wood or inadequate cutting in metals.

Understanding the thickness of your materials is equally essential. Different thicknesses require varying power settings. Reports show that a laser cutting machine can effectively cut up to 6mm of acrylic at 50 watts, but steel up to even 3mm may need about 150 watts. Many users overlook this detail, resulting in subpar outputs. Failing to match the machine’s capabilities with the material’s needs can yield disappointing results.

Additionally, consider the laser type. CO2 lasers are great for non-metallic materials, while fiber lasers excel with metals. This aspect creates another layer of complexity. It’s not just about compatibility; it’s about understanding operational limits. Many manufacturers provide guidelines, yet users often misinterpret them. The gap between expectation and reality can be frustrating. Thus, careful assessment of your material is crucial for successful laser cutting.

Evaluating Budget and Cost Considerations for Laser Machines

When evaluating budget and cost considerations for laser cutting machines, a clear understanding of your financial parameters is crucial. The initial investment can range widely. Entry-level machines may start around $5,000, while advanced models can exceed $100,000. According to a recent industry report, the average cost of a mid-range laser cutter is approximately $25,000. This means a significant commitment.

Operational costs are equally important. Consider maintenance expenses, which can average around 10% of the machine's cost each year. Electricity costs can also add up. Typical laser cutters require between 10 and 20 kilowatts per hour. If you operate for 40 hours a week, that’s a notable monthly bill. Remember, lower initial costs may come with trade-offs. Durability and service options could also be compromises.

Additionally, be aware of the hidden costs. Training for staff can be substantial. Poorly trained operators can lead to mistakes, increasing waste and downtime. It’s essential to factor in potential production delays when evaluating the total cost of ownership. A reputable report highlighted that businesses often underestimate these expenses, creating budget strains. Balancing initial costs with operational efficiency is pivotal for a profitable decision.

Cost Analysis of Different Laser Cutting Machines

Comparing Brands and Customer Reviews for Informed Decisions

When selecting a laser cutting machine, comparing brands is crucial. Customer reviews can reveal a lot about a machine's performance. Pay attention to feedback on accuracy, speed, and ease of use. Brands that consistently receive positive remarks often have solid reputations.

**Tip:** Look for reviews that describe specific experiences. Vague praises may not be very helpful. Checking forums can also offer insights on machine longevity and customer support.

Consider the material you intend to cut. Different machines excel with certain materials. Reviews might highlight strengths in cutting wood, plastic, or metal. Some machines may struggle unexpectedly, which is worth noting.

**Tip:** Take notes on repeated points in reviews. If many users mention a specific issue, it’s probably significant. Don’t ignore critical feedback even if a product looks good on paper. Product specifications don’t always tell the whole story.

Article Source:

Stay Connected

Sign up today to keep up with the newest information from one of the Southeast’s leading suppliers of fluid handling equipment!